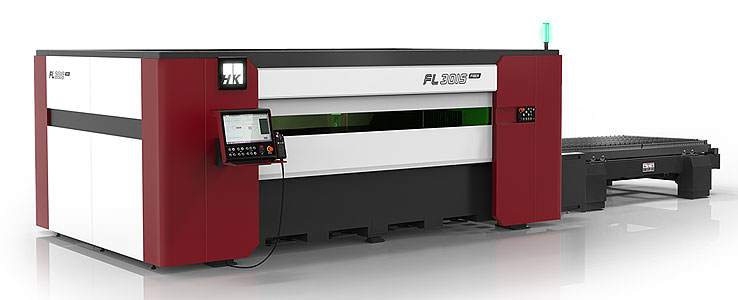

Laser Metal Cutting Machine 500w

Laser Cutting Systems� unitized cutting machine and LaserMat� II are choice laser cutting machines, offering customers high speed and precision accuracy.

Laser cutting is accomplished by using high power density energy generated by a focused laser beam. The CNC controller outputs a high frequency pulsed laser in a pulsed way to create a beam that is a particular frequency and pulse width. The laser beam is transmitted and reflected by the optical path before being focused by the lens group. The part is illuminated by a tiny, high-energy spot. This focal point is found near the surface. At an instant high temperature, the material melts and vaporizes. Each laser pulse causes a small hole to be created in the substrate. With the help of the computer numerical controller, both the substrate and laser head perform continuous relative movement according to the file. The laser head can then cut the substrate into the desired form.